Should I use 4" or 6" Boards?

This is one of the most critical decisions you make when purchasing and installing hardwood decking - if your deck is closer than 36" to the ground you should not use 6" material.

The most common complaint we get regarding hardwood decking is cupping of 1x6 and 5/4x6 boards that are installed too close to the ground, generally also installed without adequate

ventilation. A moisture difference between the bottom and top of the boards creates cupping and may lead to your deck failing.

Storage and Handling

For best results, Nova Decking should be kept out of direct sunlight and not exposed to weather before installation. Be sure you know whether you have a kiln dried or air dried product.

Air dried decking must be allowed to acclimate to approximately 18% moisture content on the job site prior to installation. To determine moisture content, be sure to use a moisture meter that is calibrated for the correct species of wood.

Kiln dried decking can be installed after a few weeks of acclimation.

Once a decking package is delivered to the job site, keep the material off the ground by placing a few pieces of lumber underneath the decking package.

Cover the material with a tarp to protect from sun damage and rain.

Material Application

Spacing: Be sure you know whether you have a kiln dried or air dried product. For Kiln Dried decking set spacing between boards at 3/16” for 4” and 1/4” for 6” decking.

For Air Dried decking, acclimate on the job site until the material is around 18% moisture content, and then set spacing between boards at 3/32” for 4” and 1/8” for 6” decking.

This space between boards will allow for air circulation, room for expansion, and provide for the proper spacing as boards become fully seasoned.

The maximum movement, shrinkage or swelling, is typically 3/16” on 4” decking and 1/4” on 6” decking.

ExoDek QuickClip Hidden Fastener

Decking Product Catalog

Span: You must consult local building codes to be sure you are following local regulations. Generally, 1x4 and 1x6 decking can be installed with joists on 16” centers.

5/4x4 and 5/4x6 decking can be installed with joists on 24” centers. When installing on an angle, joist spacing should be on 12” centers.

Final joist spacing should only be determined after consulting local building codes.

Don't Forget to Put a Vapor Barrier Under Your Deck when Close to Ground

Ground-side Ventilation: Build your deck so that the surface is at least 16” above the ground when using 1x4 or 5/4x4 decking material.

When using 1x6 or 5/4x6, the deck must be constructed a minimum of 36” off the ground. There must be adequate air circulation underneath

the deck in order to prevent cupping and warping of boards. In wet areas or over water, additional clearance is recommended.

In close to ground applications, 60” or less above ground, a vapor barrier is necessary to prevent moisture from absorbing

into the underside of the decking boards.

Wood is Stable in Length - No Spacing End to End is Required

Fasteners - Stainless Steel Face Screwed

Fasteners: Several different options are available for fasteners and for fastening techniques. We recommend stainless steel screws through the face of every board,

two screws per joist. Self-tapping stainless steel screws are available but may require pre-drilling. Pre-drilling is always required on the ends of the boards.

We do not recommend the use of non-stainless fasteners since they will cause discoloration near the fastener. Do not use carbon-steel screws.

Hidden Fasteners

Hidden Fasteners: We recommend hidden fastener clips, such as Nova's ExoDek QuickClip, shown below, that allow for the natural expansion and contraction of the

wood as it takes on seasonal moisture.

A minimum of 36” of clearance for 5/4x6 and 1x6 and 24" of clearance for 5/4x4 and 1x4 is required for adequate ventilation - leave a minimum of 50% open area around the edges of the deck.

Use netting or lattice to prevent vermin from taking up residence under your deck.

We do not recommend the use of hidden fasteners which do not allow for the boards to move naturally after installation -

this includes mechanical fastening systems which fasten from the underside or edges of the boards.

Despite manufacturers’ claims, we have determined that these products do not provide adequate anchoring of hardwood deck boards to the substructure.

Hardwood decks require a secure fastening system which locks down the boards and keeps the spacing between boards consistent.

Edge / corner fastening systems such as the CAMO Marksman and the Kreg Deck Jig do not keep the boards in place during normal shrinkage

and swelling with the seasons. We do not recommend the CAMO Marksman or the Kreg Deck Jig. Using either of these fastening systems will void any

warranty that we offer on our naturally durable hardwoods.

ExoDek QuickClip Hidden Fastener

Decking Product Catalog

Screw & Plug Systems

The other accepted method for a hidden fastener look

is the Starborn ProPlug system, as it still achieves face screwing for maximum hold-down and the use of stainless steel screws.

Manufacturer's Warranty of Durable Hardwood Against Rot & Decay

Manufacturers' warranties for hardwood decking are generally only against rot and decay, and only apply to naturally durable hardwoods such as Ipe, Cumaru, Batu, Red Balau, Yellow Balau,

Massaranduba, Torem, Merbau and Angelim Pedra.

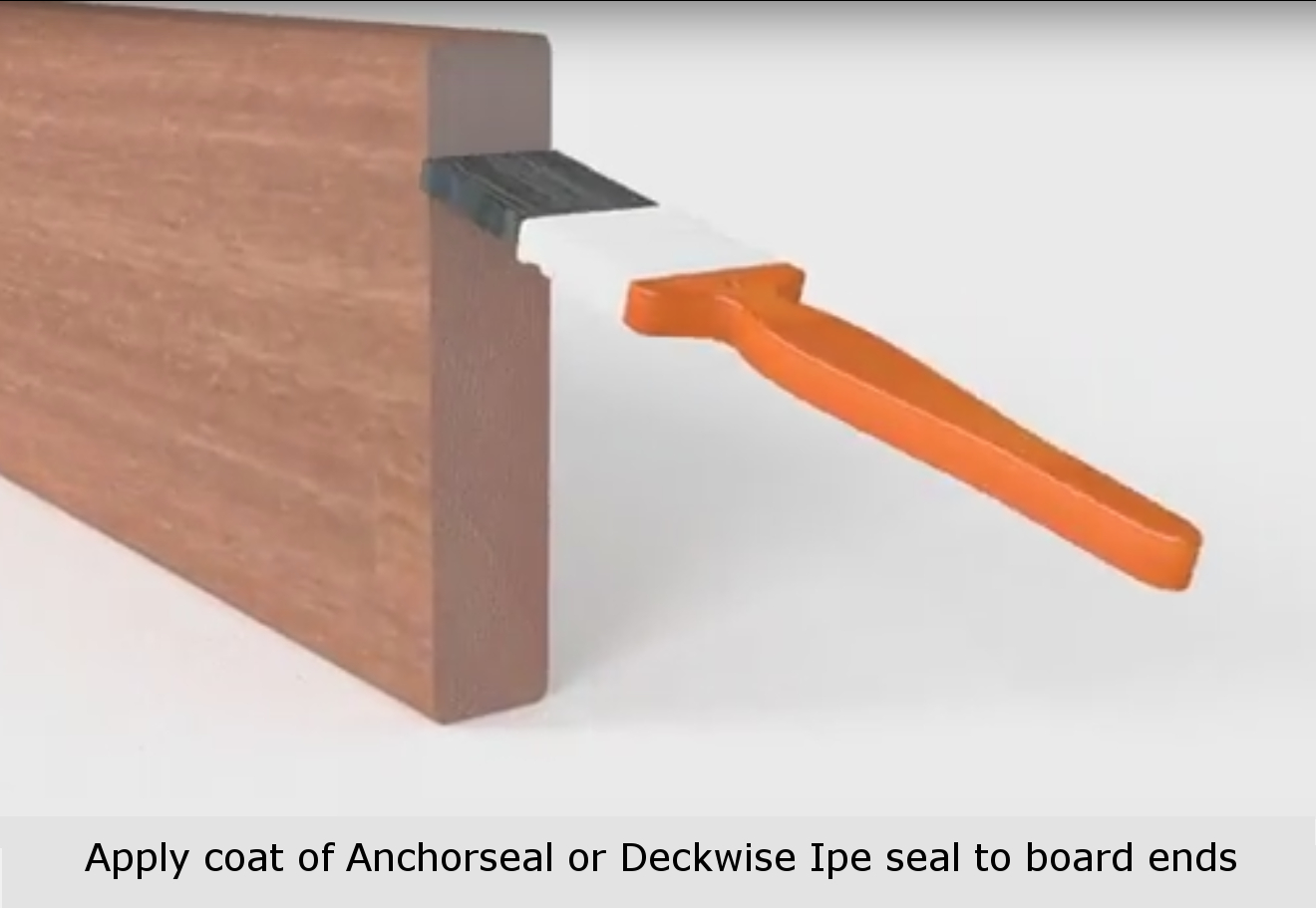

Always End Seal Fresh Cuts

End Sealer: Nova Decking is always end-sealed during manufacturing to help prevent splitting and checking on the ends of boards.

We require that the boards are end-sealed as soon as reasonably possible after cutting during installation.

A clear, water-resistant wax should be used. One such product is Anchorseal from UC Coatings, although several other products are available.

If the material is not end sealed the manufacturer will not honor any claims under the warranty.

Porch Flooring: It is recommended that all T&G exterior applications be in a covered environment and be installed with a pitch to allow for proper drainage.

Please refer to your local building codes on pitch requirements. Material should be finished on all six sides before application to prevent moisture from

collecting on the underside of the deck. T&G products do not allow spacing for ventilation, which is why only covered installations and adequate ventilation

underneath the deck are required. Fastening should be done with stainless steel fasteners.

Watch Our Hardwood Decking Installation Video

Finishing Options

In order to help prevent surface checking, cupping and discoloration, we require that Nova Decking be finished on all four sides with an appropriate and sufficiently-pigmented oil-based product, prior to installation.

Especially in dry, sunny conditions, finishing must be done prior to exposure to weather.

Deck boards should be oiled on top, bottom and edges.

Finishing Nova Decking on the underside of your deck will reduce potential cupping by inhibiting moisture from absorbing into the wood.

If a natural silver color is desired,

we still recommend finishing with a Clear or Gray oil-based finish and then letting the material naturally which will take 2 to 3 years. We do not recommend water based finishes because they do not adequately seal the wood fiber and are prone to excess checking over time.

For best results, apply the treatment according to the manufacturer’s directions. To maintain the natural color, a high quality penetrating oil finish with UV inhibitors should be used.

Nova Decking can also be pressure washed, but you must be careful not to damage the surface wood fibers by setting the pressure too high.

Pressure washing may be necessary between oil treatments in order to remove surface discoloration.

Warning: Must Follow All Directions

- 36" Off Ground for 1x6 or 5/4x6

- 16" Off Ground for 1x4 or 5/4x4

- Adequate Ventilation Below Deck

- 1/4" Spacing Between Boards

- End Cuts Sealed with Wax

- Must Use Oil Finish on All Sides

- Vapor Barrier On Ground

- Stainless Steel Screws

- Face Screw, 2 Screws per Joist (or)

- Use Hidden Fasteners Which Allow Natural Movement

Hardwood Decking Installation - Tools and Techniques

Nova Decking can be easily crosscut with a good quality chop saw using a carbide-tipped blade. Ripping can be done on a standard table saw, using a well-aligned high quality fence and a carbide-tipped blade.

When drilling, always use the highest quality drill bits available. If screwing through the face, a countersink bit with a positive stop, such as the Starborn Smart-Bit, should be used so all screw heads end up at a consistent depth. Fasteners should be pre-lubricated for easiest assembly.

Routing or planing can be done with both high speed steel or carbide cutters. Feed speed should be fairly slow. When routing be sure that the cutter head is spinning with the cutting face into the material. Sanding may be necessary before a final coat of finish is applied.

Close To Ground Applications

Many people want to build their hardwood deck closer to the ground than we recommend in our installation guidelines. Close to ground applications also include rooftop decks and any type of deck installed directly over a flat structure with less than the minimum recommended 16” of clearance.

There are a number of critical steps that must be followed in order to install decking in this manner:

Close to Ground? We recommend only 1x4, 5/4x4 or narrower boards. Never use 1x6 or 5/4x6 material in close to ground applications.

Spacing between boards: You must allow space for your deck boards to expand when they take on moisture, as they will inevitably do when exposed to wet weather, rain or high humidity. The final spacing should be at 1/4” if you have material with a moisture content in the 10-12% range and relative humidity in the 35-45% range. If you are installing during very dry conditions and the boards are measuring in the 6-8% range, then you should add 1/16” additional spacing so that your deck can handle higher humidity and rain. If you are installing high moisture content material, such as Air Dried Ipe in the 16-18% range, then a gap of 3/16” is appropriate so that material does not gap too much in dry weather.

There is a specific science behind the required gap which is a function of the exact wood species, the beginning moisture content of the wood and the dry and wet extremes you want your deck to handle. In most cases, you should plan for 100% humidity levels and expect that the deck boards will expand to their maximum amount at the fiber saturation point of the wood. The dry side of the equation has more variability since many areas of the country have typical minimum humidity levels. You don’t need to plan for bone dry conditions in the Southeastern United States, for example; but you certainly do need to plan for bone dry conditions in Arizona and Central California.

Shrinkage and Expansion: The amount of expansion from bone dry to fiber saturation is given by tables in references such as The Wood Handbook. The rate of movement is linear with respect to the moisture content from bone dry (0%) to fiber saturation (generally around 25%). Most hardwoods can be expected to move around 8% which is 0.28” for a 3.5” board. This is the maximum movement from bone dry to fiber saturation.

Typical hardwood species such as Batu, Cumaru and Angelim Pedra (as well as many others not sold by Nova) have movement up to 8%. The ONLY hardwood species which is significantly more stable is Ipe, which has a total movement in the 5-6% range. We always recommend Ipe as the best hardwood species when building close to ground.

Ipe will exhibit less tendency to cup, warp and or check as changes in moisture content occur. However, all hardwood decking species will exhibit some degree of checking, cupping and warping when allowed to fluctuate from very dry to very moist conditions.

The best way to minimize this movement is to slow the flow of moisture into and out of the boards. We recommend waxing the underside with a typical end seal wax product. Wax should be applied on the raw wood - it is not necessary to coat the material with oil finish if wax is being used on the back side. An oil finish should be applied on the face and edges of every board during installation. Oiled boards may still be waxed on the bottom side provided that the oil allows the wax to penetrate and provide a moisture seal. Some sanding or cleaning with solvent may be required in order to get the wax to properly adhere to the previously oiled boards.

The only reason a hardwood deck fails when close to the ground is INCORRECT INSTALLATION. Nova’s warranty is against rot and decay - it does not cover shrinkage and expansion.

ExoDek QuickClip Hidden Fastener

Decking Product Catalog

Safety Concerns:

Safety glasses and a dust mask should always be worn when working with hardwood lumber. We recommend an active carbon filter dust mask. Some people may have an allergic reaction to hardwood dust. Remove wood slivers immediately to prevent infection.

WARNING:

Drilling Sawing, sanding or machining wood products generates wood dust, a substance known to the State of California to cause cancer. Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection.

Disclaimer:

Our tropical decking products are carefully manufactured and inspected to ensure quality. However, these products are natural wood products and are subject to variations in weight, density, color, grain and performance. Wood decking is subject to dimensional changes as the moisture content in the wood fluctuates with humidity in the air. Swelling, shrinkage, checking, and other movement of individual pieces are normal occurrences in wood decking.

Local building codes must be consulted when building an exterior deck. Most counties require building permits.

And Finally...

Call the experts at Nova if you have any questions.

Product Resource Information:

ExoShield - Pure Tung Oil Exterior Wood Stain

www.novausawood.com/exoshield

1-503-419-6407

ExoDek QuickClip - Hidden Deck Fasteners

www.novausawood.com/hidden-deck-fasteners

1-503-419-6407

UC Coatings - Anchorseal

www.uccoatings.com

1-888-363-2628

Starborn Industries

Headcote Screws, Smart Bit,

ProPlug Fastening System

www.starbornindustries.com

1-800-596-7477

Contact Us

Call Us